Rocker arms - quality and affordable price page 1 of 2

$ 900.0

$ 1000.0

$ 585.0

$ 650.0

$ 1080.0

$ 1200.0

$ 895.5

$ 995.0

$ 990.0

$ 1100.0

$ 360.0

$ 400.0

$ 427.5

$ 475.0

$ 360.0

$ 400.0

$ 787.5

$ 875.0

$ 2565.0

$ 2850.0

$ 360.0

$ 400.0

$ 360.0

$ 400.0

$ 360.0

$ 400.0

$ 360.0

$ 400.0

$ 360.0

$ 400.0

$ 360.0

$ 400.0

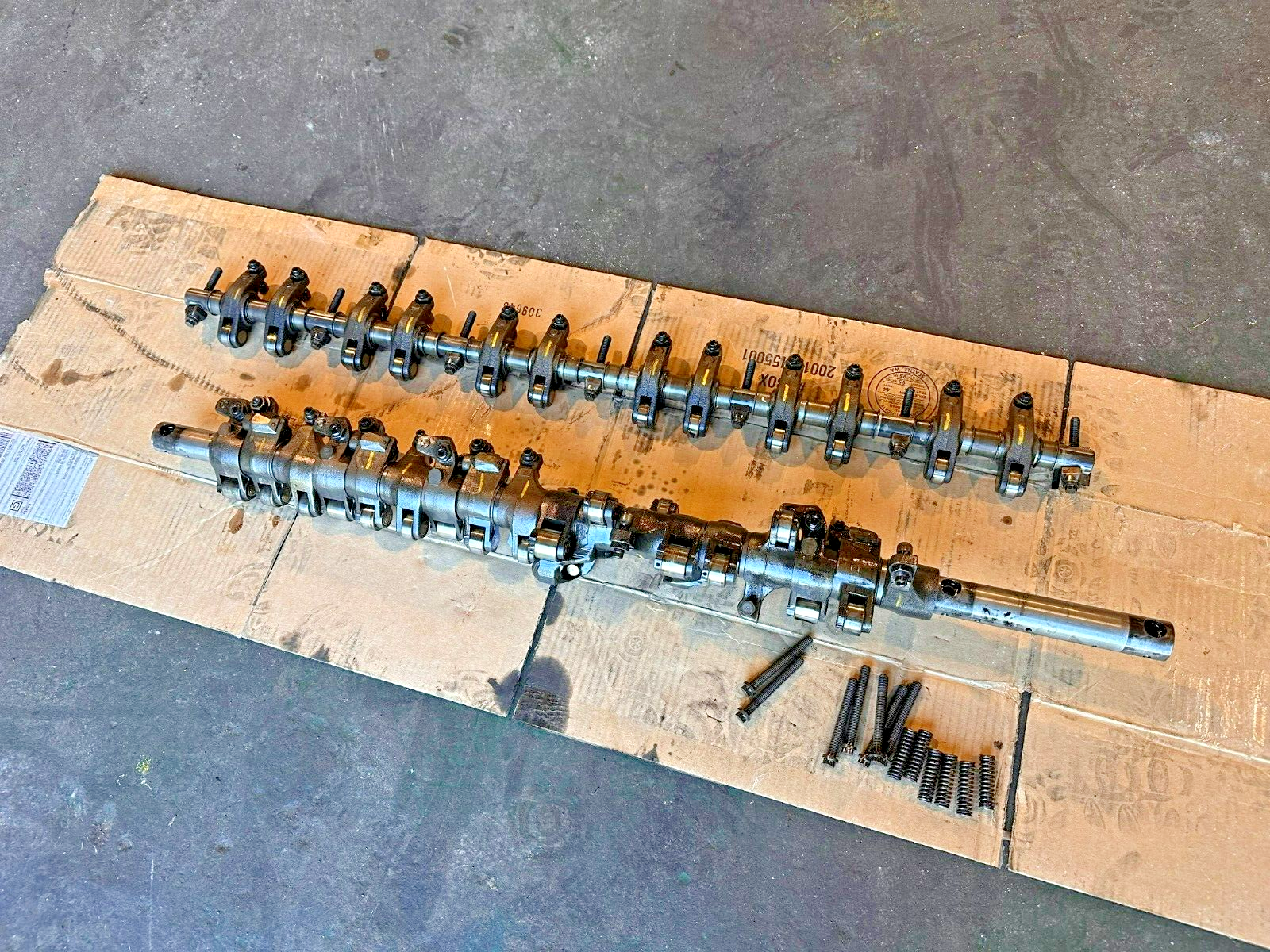

Rocker Arms

This category features rocker arms designed for heavy-duty diesel engines in trucks. These components are responsible for transferring motion from the camshaft to the engine valves, ensuring precise timing of air intake and exhaust.

Technical Functionality and Applications

Rocker arms act as mechanical levers that convert camshaft motion into the opening and closing of engine valves. Precision engineering ensures minimal flex during operation, preserving valve timing accuracy and improving combustion efficiency. Designed for compatibility with truck brands like Freightliner, Kenworth, Mack, and Volvo, these rocker arms are crafted from high-strength alloys to withstand the stress of high-pressure cycles and elevated temperatures typical of long-haul operations. Advanced features include reduced mass to minimize inertia and hardened surfaces to resist wear, contributing to smoother valve operation and extended engine life. Proper alignment and lubrication of rocker arms are critical for preventing premature wear of valve components and maintaining consistent performance under heavy loads.

Unique Features and Cost Efficiency

Used rocker arms offer a reliable, cost-effective solution for engine repairs. Each unit is inspected for wear on pivot points, cracks, and spring tension to ensure it meets operational standards. Unique to this category, some rocker arms include built-in lubrication channels that enhance oil flow to valve assemblies, reducing friction and improving thermal management. Opting for used rocker arms significantly lowers the price of maintenance while ensuring high durability and performance. Truckers rely on these components to maintain peak engine output, especially in vehicles tasked with frequent towing or hauling heavy payloads over long distances. Investing in quality-tested rocker arms minimizes repair costs and downtime while extending the operational life of other critical engine components.